Brief introduction of fruit shell pellet production line:

The fruit shell is used as raw material, which is solidified and extruded into high-density biomass particles by pretreatment and processing.

The pellets fuel can be used for burning, barbecue, and fireplace heating, and the combustion efficiency is over 80%;

and the sulfur dioxide, ammonia nitrogen compounds, and dust generated are less.

Raw materials:

There are mainly shells or residual of fruits like nuts shells, apple residual and peanut shells, and so on.

Process introduction:

After the shell is ground by a hammer mill, then it is granulated. The processed finished granules are 6-10mm in diameter,

and the granules are cooled and packaged for transportation and sale.

This project is a 1t/h fruit shell and waste biomass production line, the total power of the equipment is about 145kw,

and the workshop covers an area of 800m2, which contains raw material warehouse and finished product warehouse.

The whole line is compact in design, reasonable in structure, and meets environmental protection requirements.

And can be customized design according to customer requirements.

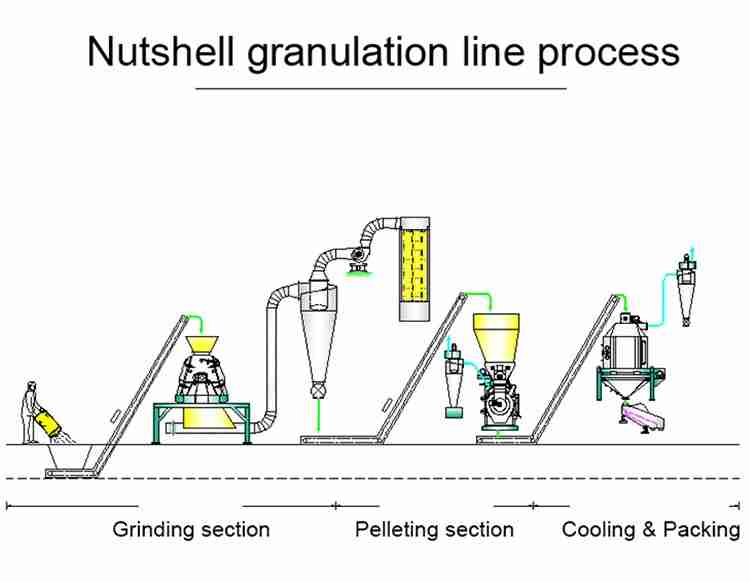

technological process:

grinding process-granulation process-cooling and packing process

technological characteristics and introduction:

Grinding process: there is no dust discharge in this process. After grinding,

it is transported and pneumatic transmission by the fan suction air pressure.

The hammer mill is a water droplet type structure;

the hammer mill rotor can be operated in forward and reverse directions to improve the service life of the hammer blade;

the direct transmission mode of the motor is adopted.

Granulation process:

The diameter of biomass pellet is 6-10mm optional, and the biomass pellets have the characteristics of high calorific value,

no pollution and low ash content, which can be widely used in biomass power plants, biomass steam boilers,

household fireplaces, drying furnaces, and biomass gasifiers.

Cooling & Bagging process:

used to reduce pellets temperature and decrease pellets moisture,

pellets temperature is not higher than ambient temperature 5 ℃ after cooling and the pellets moisture around 8-10%,

The process can be optimized according to different customer needs:

1. Dryer will be needed if the moisture of sawdust is higher than 20%, the moisture of sawdust should be dried to 13-15% by dryer before pelleting.

2. The packing machine can be adjusted according to customers’ requirements for bag size. Bulk or silo storage is also optional.

| Moder | 1T Fruit Shell Biomass Pellet Production Line |

| Grinding equipment | MFSP56*40, power 37kw, design with 1T/H output |

| Pellet mill | MZLH420, main motor power: 90kw, power of forced feeder: 0.75kw, design with 0.8-1.2T/H output |

| Cooling equipment | MKBZ120, design with 1-2t/h output |

| and the workshop covers an area of 800m2 | |

Contact Us