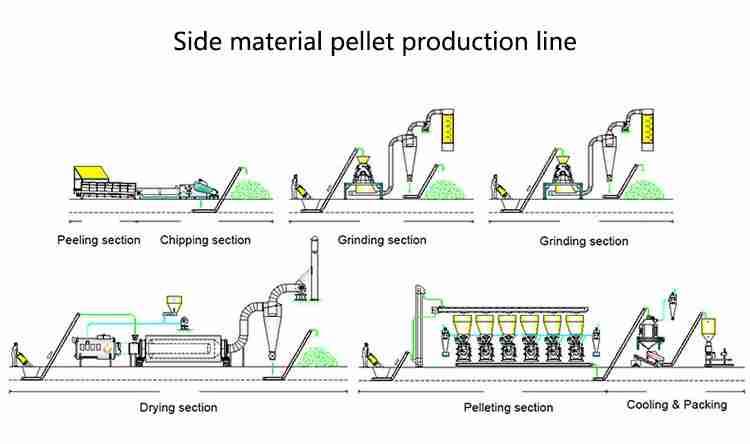

side material pellet production line:

Wood or wood products processing plant waste as raw materials, after pretreatment and processing, solidification extrusion into high-density granular fuel.

Raw materials:

raw materials are mainly scraps, sawdust or sawdust, and other small wood.

Process introduction:

Make the leftover material into wood chips with 20-30mm dimension and 5-10mm thickness by chipping machine,

then finely ground into sawdust with 3-4mm by hammer mill.

The raw material moisture will be dried to about 15% through the three-layer drum dryer.

The wet sawdust will not be crushed and directly into the dryer to dry. Finally, they will go to the pellet mill to make pellets.

The final pellet diameter is optional from 6-10mm. After pelleting and cooling,

it will be packed into silos or 20-50kg/ bag by small bag packing scale for convenient transportation and sale.

This Leftover material pellet production project can produce biomass pellet 10tons per hour and has a total power of 1848kw,

the area of the workshop is about 3600m2 including the raw material warehouse and finished products warehouse,

the whole line is characterized by a compact design and reasonable structure and satisfied by environment protection requirements,

meanwhile, it can be directed to customers’ design.

Process flow:

Chipping process–Grinding process–screening process–drying process–mixing process– pelleting process–storage process– bagging process

chipping process:

( only part of the leftover material need chipping):

the leftover material is chipped into wood chips with 20-30mm dimension and 5-10mm thickness then go to the following process.

Grinding process:

The grinding work has no dust discharge.

After grinding, the sawdust will be transported through pneumatic transmission by the fan suction air pressure.

The hammer mill is a water droplet type structure;

the hammer mill rotor can be operated in forward and reverse directions to improve the service life of the hammer blade;

the direct transmission mode of the motor is adopted.

Drying section:

three-layer drum dryer, after drying, sawdust moisture in about 15%.

Mixing section:

the sawdust or shavings of different tree species and other raw materials will be mixed through the mixing machine,

and then into the pellet mills for pelleting.

Granulation process:

The diameter of biomass pellet is optional from 6-10mm, and the biomass pellets have the characteristics of high calorific value,

no pollution and low ash content, which can be widely used in biomass power plants, biomass steam boilers,

household fireplaces, drying furnaces, and biomass gasifiers.

Storage process:

1 unit of 5000T finished pellet silo for storage. The finished pellet can be temporarily stored in the silo and for bulk shipment.

According to the customer’s local sales needs, the appropriate packing scale is selected for customers to sell products more easily.

There are usually two specifications: small bag and ton bag. 20-50kg/bag for small bags, 500-1000kg/bag for ton bags.

Highlights and optimization of the scheme design:

1. This scheme adopts the separation method between the raw material pretreatment workshop and the finished pellet workshop.

The dust pollution in the raw material pretreatment workshop will not affect the finished pellet workshop.;

2. To meet customers’ requirements of reducing floor space, the design of the main workshop is of high height.

Users can increase the floor area according to their actual needs, thus reducing the height of the main workshop;

3. In this scheme, the customer requires that there is mainly sawdust of two different tree species,

which needs to be mixed in a certain proportion for pelletizing. If there is no such requirement, the mixing section before the pelletizing section can be removed.

4. According to the actual market demand, users can select and match the storage and packaging forms of finished products,

such as small package, ton package, silo storage, bulk distribution, and other forms.

| Moder | 10t SIde Material Pellet Production Line |

| Chipping equipment | Wood chipper LYGX216,main machine power: 55kw,Feeding roller power: 3kw,designed output: 10m³/h |

| Grinding equipment | MFSP68*120,power 200kw,capacity: 6-8T/H( raw material moisture 40%) |

| Cleaning equipment(3sets) | MCY160*300, power 3kw, designed output 5-8T/H/set, separately for cleaning wet sawdust before drying, and sawdust before pelleting |

| Drying equipment(1set) | LYHG50, drum diameter 3.0m, length 11.6m, power 19kw, design yield 5T, (before drying raw material moisture is 40%) |

| Mixing equipment | SLHY5, host power 30KW, continuous ribbon mixer |

| Pellet mill(12sets) | MZLH420, main motor power: 90kw, power of forced feeder: 0.75kw, design with 0.8-1.2T output |

| Cooling equipment | MKLB4, cooling volume: 4m3, design with 5-7t/h output |

| Packing scale | MDBLY-K,bag size20-50kg/bag,packing speed: 3-5bag/min |

| the area of workshop is about 3600m2 | |

Contact Us